TGS

Simulation Compressor Plant - Training TGS Operators

Simulation

#EDU #OIL #CFD #MYS

OBJECTIVE OF THE PROJECT

Develop a tool that contains all the necessary functionality for the training of operators of a compressor plant.

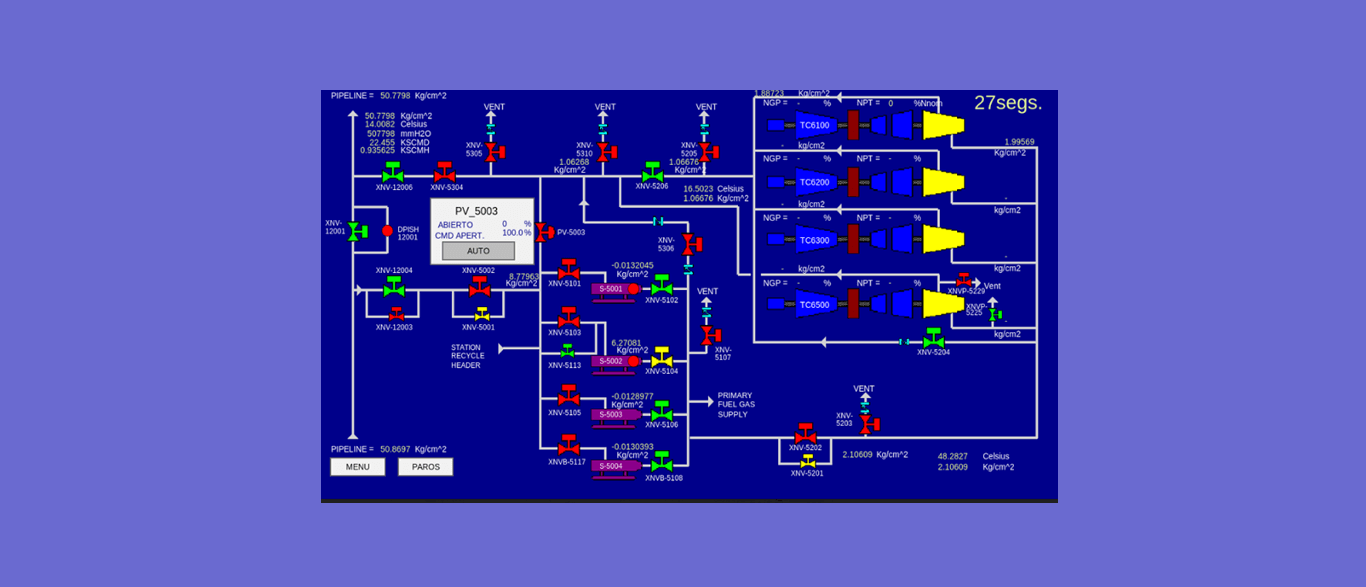

On the one hand, a model of simulation that represents reality was taken into account and, on the other hand, a graphic interface with a look & feel equal to that used by the operators, so that they find an identical environment with which They work every day.

CHARACTERISTICS

Profiles

The Instructor profile will be able to create Scenarios that could happen in a compressor plant.

The Student profile can solve it, operating on the simulation.

Scenarios

- Initial state of the plant (certain valves open or closed, a running compressor, an open safety valve, etc.)

- Events, which are situations that create a change in the initial state (compressor failure, accidental opening of a valve, etc.)

These events will occur at predefined moments in the Stage itself and / or triggered by the Instructor from their control screen, all of them ignored in principle by the Student.

Each action of the Student will be simulated delivering on screen a system identical to the one that would have access in the plant.

Finally, the Instructor has the possibility to review the Resolution, which is kept in the student's history, in order to make the correction and the corresponding comments.

TECHNOLOGY

- The simulation engine has been programmed in C ++ language.

- The calculation engine interface is a friendly and intuitive Java application, aesthetically and functionally similar to the one used by the operators.

- The database used is Oracle, and the Apache Tomcat application server.

ARCHITECTURE

The application runs under a client-server architecture as indicated by the diagram.

The client application can be accessed from any PC, through an Internet browser such as IE or Google Chrome, and with Windows 2000 onwards.

CONCLUSION

Candoit developed the ability to simulate a dynamic and complex process as is the operation of a compressor plant.

The interdisciplinary team of Candoit that developed both the calculation engine and the interface did it in a modular way so that the components could be reused for a new plant configuration, which allows us to generate another simulator in a significantly shorter project time.